Inspired by the excellent video I posted about yesterday, and constrained by the weather (it is raining and my “work area” is outside) I set about planning out how I’m going to do the top carve. On a Les Paul there are two different parts to the carve: The first is the traditional archtop shape we all know and love, the second was something of a revelation to me – the top is carved flat, rising from where the neck join starts to where the finger board finishes. This means that despite having an angled neck, the fretboard still runs parallel to that part of the body.

Whilst it is not a Les Paul, this picture from the MyLesPaul forum really clearly shows the two different parts of the carve.

So tackling these two carves separately, first off I taped some translucent paper over the body, marked up the centre-line, and for the top half of the guitar roughed out the two main steps for the carve (highest and lowest) freehand with a pencil.

I folded the paper along the centre-line and then replicated the shapes for the bottom half of the body.

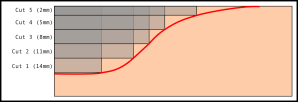

I bisected the two lines to draw the third step, again, freehand. The maple top is 19mm thick and I want to leave the edge at 5mm, so for the low step I’ve got to rout away 14mm. The top step is going to be a depth of 2mm. The centre step therefore will be 8mm. I may yet decide to add two further steps at 5mm and 11mm depth, just to minimise the amount of sanding I’ll need to do. This diagram gives you a rough outline of what I have in mind (not to scale).

The next step will be to turn my paper template into router templates, using 6mm MDF sheet. I’ll start by cutting the paper to lowest step, transferring that to the MDF, cut the paper to the next step, transfer to the MDF… and repeat all the way up to the top step. This will leave me with up to five templates.

One of the things that concerns me is that, while cutting around these templates, it is very easy for the router to tip away from the vertical, and cut too deep, and at an angle. To guard against this I’m going to build a box to fit around the guitar body, and a large footplate to ride on top of this box. This will guarantee (I hope) that the router always remains vertical.

An added benefit will be that hinging the box at the front side, and shimming up the back will allow me to cut the neck pocket and the flat front-to-back carve at exactly the right angle. I was inspired to this approach by reading this “Luthier Than Thou” article about carving Les Paul tops and neck pockets. I’m going to adapt the same basic principle to kill two birds with one… er… wooden box.

Update: I’ve since found a picture of exactly what I had in mind on the MyLesPaul forum.

I admire your ambition. If I ever build a guitar I will keep the woodwork as simple as possible. I’ve not got a lot of tools anyway. Looking forward to seeing how it turns out.

Rather than ambition, it is more of a case of “when life gives you lemons, make lemonade”. I inherited a body blank that already has a 19mm cap on it. The only reasonable option is to have a go at carving the top. It’ll certainly give me the chance to learn plenty while I’m building this one!

okay so i cant find anyone who would do this i know it would cost be but idc what would i have to do to get ya to make this for me?

I’m really flattered but I’m going to say no.

I’ve really enjoyed building guitars for myself, but if it was for someone else it stops being a hobby and starts being a job. I’m still working out how to do stuff and it takes me ages and ages – probably 2 or 3 times as long as an experienced builder would take. If I was to calculate it at an hourly rate it would cost several times more than that quote you’ve had from Prariewood.

BTW: Whereabouts are you? Is that two grand you mentioned in US dollars? I had initially thought you’d meant UK pounds. $2000 is pretty reasonable for a custom built guitar. You may find something cheaper, but not by much.

I forgot to mention, if you’re interested in alternative quotes I’d suggest you contact Steve at Benford Guitars (http://www.benfordguitars.com/). He built a guitar for me last year and I’ve not come across anybody producing better work, at more reasonable prices.

its all goode man! and im in the US! but ya prariewood is the only one who will do it everyone else wants like 4 grand sometimes 5 cus its not there model and ill def check out steve!

Tell Steve I said “hello”! You can see pictures of the one he built for me at http://www.benfordguitars.com/davemac.html

but ya man you have a talent thats such a beautiful guitar i wann alearnt o build i have been making some amps but i dont have tools for wood working =( good job on all the ones ya made